- +86-19941574798

- sale06@kfqizhongji.com

Amusement Equipment Wheels

High Wear-Resistant Polyurethane Wheels for Roller Coasters

High wear-resistant polyurethane wheels for roller coasters are characterized by low rolling resistance, high load durability, smooth ride, chemical corrosion resistance and high durability (low maintenance cost).

High wear-resistant polyurethane wheels for roller coasters can meet the requirements of fast speed, multiple speed changes, smooth operation, safe and stable use of roller coasters with their low rolling resistance, high load durability, smooth driving performance, chemical corrosion resistance, and high durability (low maintenance cost). The following is a detailed introduction to the structure and advantages of polyurethane roller coaster wheels.

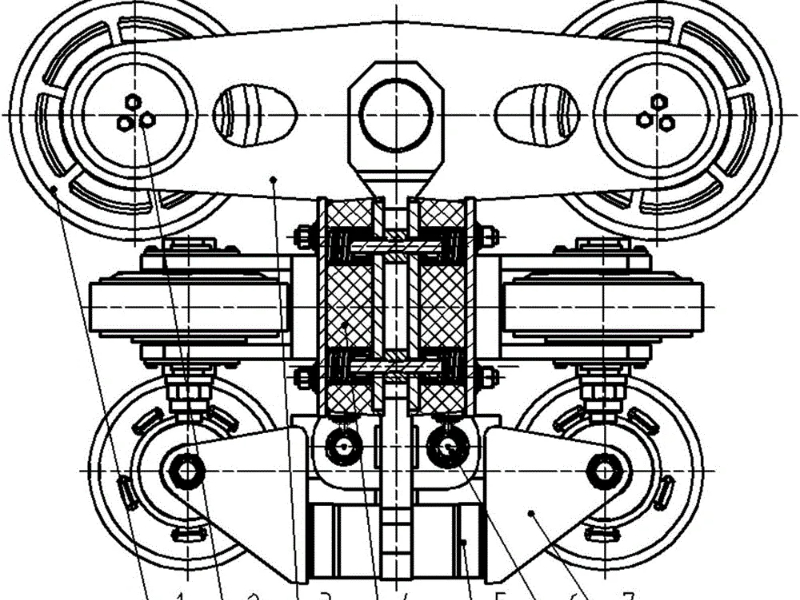

Structure of roller coaster wheels

The roller coaster wheel is not a single wheel but consists of at least 3 wheels in different directions. The polyurethane wheel frame structure generally consists of a road, side friction, and up stop wheel. A set of wheels on each left and right track firmly hold the roller coaster on the track from three directions.

The road wheel carries the load or weight of the train and bears the maximum load.

The side friction wheels are also called guide wheels. They are installed on the inside or outside of the track according to the track type, perpendicular to the road wheels. The wheels can be flexibly turned according to the track type.

The up-stop wheel is installed under the track to prevent the coaster from derailing on the air ramp or stalling when inverted.

Why choose injected PU wheels for roller coasters?

• Low rolling resistance: The greater the force applied to the tire, the greater the rolling resistance coefficient. This requirement prompts designers to choose harder wheel materials. The hardness of polyurethane wheels can range between 80 and 95A, and the hardness can also be customized according to actual needs.

• High load durability: In a high-speed dive, the wheel must not only bear the weight of passengers and carriages but also withstand a force six times its weight while the train maintains high speed. This once again shows the need to choose a hard material. Polyurethane also has high wear resistance and is not easy to tear or debond.

• Smooth driving performance: From the perspective of tourist experience, the most important requirement is to make the ride experience as smooth as possible. Polyurethane wheels can absorb vibrations or shocks generated during operation.

• Chemical corrosion resistance: Polyurethane-coated wheels have a certain chemical inertness, do not easily react with oils, acids, and alkalis, are UV-resistant, and are suitable for outdoor use.

• High durability (low maintenance cost): After vulcanization, the cast polyurethane wheel has the advantages of high load-bearing, high wear resistance, tear resistance, and is not easy to debond, which can reduce downtime and maintenance costs. However, daily inspection and maintenance work are still required.

Philson is a wheel manufacturer with more than 20 years of experience in polyurethane casting, more than 10 formulations, and can customize low-flame-retardant, anti-static, high-temperature, and low-temperature resistant wheels. Welcome to contact us for a quote.

Polyurethane Driving Spinning Ferris Wheel

none