- +86-19941574798

- sale06@kfqizhongji.com

Semiconductor Workshop Equipment

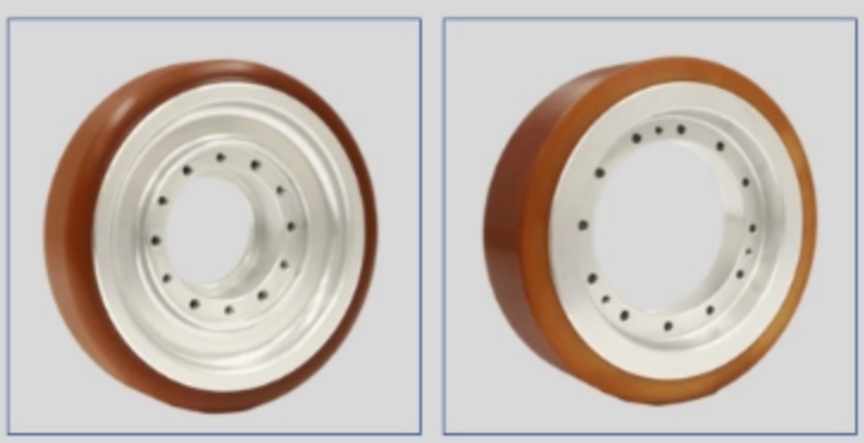

LCD Panel Cleanroom Polyurethane Drive Wheel

LCD panel cleanroom polyurethane drive wheels are engineered to meet the ultra-strict demands of LCD manufacturing, where contamination control, precision, and reliability are critical.

LCD panel cleanroom polyurethane drive wheels are engineered to meet the ultra-strict demands of LCD manufacturing, where contamination control, precision, and reliability are critical. These wheels ensure smooth, particle-free movement of conveyor systems, robotic arms, and transport equipment handling delicate glass substrates. Below, we explore their design, applications, and key benefits.

Contamination-free operation for pristine environments

Cleanroom polyurethane drive wheels feature non-porous, non-shedding surfaces to prevent dust or micro-particle generation. Their seamless polyurethane coating over stainless steel cores eliminates debris, ensuring compliance with iso class 1-5 cleanroom standards. This is vital for maintaining defect-free production of LCD panels, where even nanoscale contaminants can ruin displays.

Anti-static properties for ESD-sensitive processes

Cleanroom polyurethane wheels incorporate conductive additives to neutralize electrostatic charges. This prevents electrostatic discharge (ESD), protecting fragile thin-film transistors (TFTs) and liquid crystal layers during transport. Such protection is crucial in assembly lines where static could damage sensitive electronic components.

Precision drive systems for accurate alignment

Polyurethane-coated wheels deliver micron-level accuracy in conveyor and robotic systems. Their high-tolerance design ensures consistent torque transmission, enabling precise positioning of glass substrates during cutting, coating, or inspection stages. This precision minimizes alignment errors and enhances production yields.

Chemical resistance to harsh cleaning protocols

Cleanroom polyurethane wheels withstand aggressive cleaning agents like isopropyl alcohol, ammonia, and plasma treatments. Their resistance to chemical degradation ensures longevity in environments requiring frequent sanitization, such as photolithography or etching zones.

Low vibration for delicate glass handling

Travel wheels dampen vibrations caused by rapid acceleration or deceleration. The polyurethane’s shock-absorbing properties prevent micro-cracks in glass substrates during transport, which is critical for maintaining structural integrity in ultra-thin LCD panels.

Durability in high-speed manufacturing

Urethane drive wheels resist abrasion and deformation, even under continuous 24/7 operation. Their robust construction minimizes wear, reducing downtime for maintenance in high-throughput facilities producing screens for smartphones, TVs, or monitors.

Compliance with cleanroom safety standards

Polyurethane-coated wheels meet low flame-retardant (UL94 V-0) and non-outgassing requirements. This ensures safe operation in oxygen-rich environments and prevents chemical emissions that could compromise air purity in cleanrooms.

LCD panel cleanroom polyurethane drive wheels are indispensable in modern display manufacturing, where precision and contamination control define success. From ESD-safe drive systems to vibration-dampening transport solutions, their advanced design addresses the unique challenges of LCD production. By integrating these wheels, manufacturers enhance yield rates, reduce defects, and maintain stringent cleanroom compliance in a highly competitive industry.

Clean Room Crane Stainless Steel Polyurethane-Coating Wheels

Photolithography Machine Polyurethane Guide Wheel