Polyurethane-Covered Bearing Wheels

Polyurethane-covered bearing wheels combine durability, noise reduction, and floor protection. Their performance depends on the wheel core material, size, load capacity, and design for a specific application.

Technical Information

Polyurethane-covered bearing wheels combine durability, noise reduction, and floor protection. Their performance depends on the wheel core material, size, load capacity, and design for a specific application. Below, we'll explore the sizes, load capacities, and common use scenarios for different bearing wheels.

Size

Diameter: Larger wheels (6-10 inches) can easily handle uneven floors and heavier loads common in industrial environments. Smaller wheels (2-4 inches) are suitable for compact equipment, such as office chairs or lightweight carts.

Width: Wider wheels can improve stability and weight distribution, which is important for transporting large items. Narrower designs can save space and increase flexibility in tight spaces.

Bearing size: The size of the bearing affects how smoothly the wheel rotates. Larger bearings run smoother and quieter; smaller bearings have more friction but are better suited for lighter applications.

Pro tip: Choose the right wheel size based on the type of flooring you're using—larger diameter wheels can protect delicate surfaces like epoxy floors, while smaller diameter wheels are better for smooth, flat floors.

Load capacity

Dynamic load capacity:

This refers to the weight a wheel can handle while in motion. For example, a wheel rated for 300 lbs of dynamic load can only handle up to 300 lbs of weight while in motion.

Static load capacity:

This refers to the maximum weight a wheel can handle while stationary. This is usually higher than the dynamic load rating (e.g., 500 lbs of static load vs. 300 lbs of dynamic load).

Polyurethane rubber wheel parameters

| Performance | Properties | Product parameters | |||||

| Hardness | PU hardness at 20℃ | Shore | 75A | 80A | 85A | 90A | 95A |

| Tensile strength | Tensile strength | MPa | 18 | 26 | 35 | 38 | 45 |

| Elongation at break | Elongation at break | % | 600 | 580 | 550 | 530 | 500 |

| Tear strength | Tear propagation resistance: | kN/m | 50 | 60 | 73 | 105 | 120 |

| (without nick) | |||||||

| Abrasion | Abrasion loss | mm³ | 45 | 40 | 30 | 30 | 30 |

| Density | Density | g/ cm³ | 1.14 | 1.14 | 1.15 | 1.16 | 1.17 |

| Operating temperature | Working temperature | ℃ | -60~70℃ | ||||

| Resilience | Resilience | % | 50 | 55 | 50 | 48 | 40 |

| Compression set | Compression set | % | 25 | 23 | 22 | 20 | 18 |

| (deflection/22h/70℃) | |||||||

| Poisson's ratio | Poisson's ratio | / | 0.5 | 0.48 | 0.46 | 0.44 | 0.39 |

| Modulus of elasticity | Modulus | MPa | 5 | 20 | 40 | 60 | 80 |

| Coefficient of friction/steel | Friction coefficient/steel | / | 0.8 | 0.75 | 0.6 | 0.5 | 0.45 |

Applications

Industrial and warehousing: Steel core wheels with thick polyurethane coatings can handle heavy loads (e.g., pallet trucks, machine trucks). Choose wheels with larger diameters (8 inches and up) and higher dynamic load ratings.

Medical and laboratory equipment: Aluminum core or stainless steel wheels with non-marking polyurethane ensure quiet, sterile operation. Ideal for hospital beds, IV poles, or mobile lab carts.

Outdoor and rough terrain: Reinforced polyurethane-coated wheels with wide treads and steel cores can travel on gravel, grass, or uneven surfaces. Commonly used in shield machines, coal mine monorail cranes, etc.

Why choose polyurethane-coating wheels?

Shock absorption: Reduces impact on equipment and the floor.

• Noise reduction: Quieter operation compared to metal or hard plastic wheels.

• Floor-friendly: Non-marking and scratch-resistant.

• Durable: Resistant to wear, oil, and moisture.

From giant steel core wheels that can carry tons of weight to stainless steel wheels that can move flexibly in sterile environments, polyurethane-coated bearing wheels can meet various needs. Whether it is a busy factory floor or a noise-sensitive hospital, you can prioritize the wheel core material, size, and load capacity according to the application scenario. By understanding these factors, you will be able to invest in wheels that can improve productivity, safety, and cost-effectiveness.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

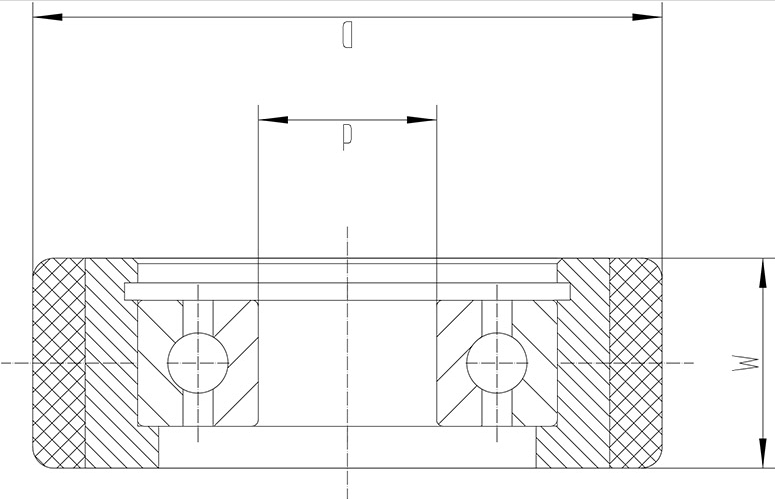

Polyurethane Tread Guide Wheel

Aluminum Polyurethane Rubber Wheels