Polyurethane Tread Guide Wheel

Polyurethane tread guide wheels have become the first choice for many industries due to their unique material properties and diverse structural designs, stable operation, high precision, high load, and suitability for complex environments.

Technical Information

Polyurethane tread guide wheels have become the first choice for many industries due to their unique material properties and diverse structural designs, stable operation, high precision, high load, and suitability for complex environments. This article will systematically discuss the functional positioning of guide wheels, the advantages of polyurethane materials, the classification of wheel cores, and typical application scenarios.

The role of the guide wheel

The main function of the guide wheel is to guide the mechanical equipment to run smoothly along the predetermined track or path to ensure the stability and positioning accuracy of the equipment. In the conveying system, the guide wheel cooperates with the guide rail to ensure the accurate positioning and smooth movement of the conveyor or other mobile equipment. In addition, the guide wheel can also withstand certain radial and axial loads, and evenly transfer the concentrated load to the track through elastic deformation, disperse the stress generated during the operation of the equipment, reduce local wear, and extend the service life of the equipment.

Characteristics of polyurethane wheels

As a polymer elastomer material, polyurethane has the following significant characteristics:

Super wear resistance: Polyurethane materials have excellent wear resistance and can maintain good use status in high-frequency and high-load working environments, extending the service life of guide wheels. The wear loss can be as low as 40mm³ (DIN standard), and the service life is 3-5 times that of rubber wheels29

Elasticity and shock absorption: Polyurethane has good elasticity and shock absorption performance, which can effectively absorb the vibration and impact generated during the operation of the equipment, reduce noise, and improve operating comfort.

Corrosion resistance: Polyurethane has strong resistance to a variety of chemical substances and is suitable for various complex environments, especially in the presence of corrosive media such as oil, solvents, etc.

High load-bearing capacity: The high strength of polyurethane materials enables them to withstand large loads and meet the needs of heavy equipment.

Processing flexibility: Polyurethane materials are easy to process, and guide wheels of different hardness, colors, and shapes can be customized according to different needs to meet diverse application needs.

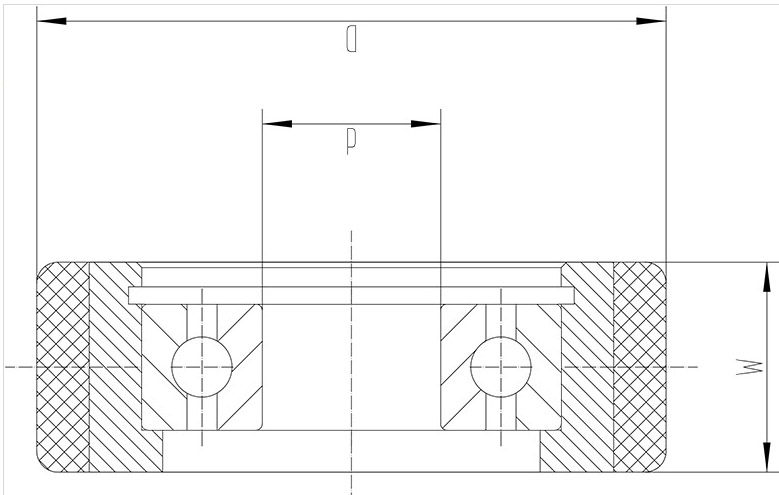

| Material code | Model | Wheel diameter (mm) | Wheel width (mm) | Axle diameter (mm) | Load (kgs) |

| KH60/20/6203 | 60 x 20 | 60 | 20 | 6203 | 90 |

| KH60/25/6200 | 60 x 25 | 60 | 25 | 6200 | 120 |

| KH70/20/6004 | 70 x 20 | 70 | 20 | 6004 | 110 |

| KH70/25/6204 | 70 x 25 | 70 | 25 | 6204 | 140 |

| KH70/30/6205 | 70 x 30 | 70 | 30 | 6205 | 160 |

| KH75/20/6204 | 75 x 20 | 75 | 20 | 6204 | 120 |

| KH75/25/6204 | 75 x 25 | 75 | 25 | 6204 | 150 |

Classification of guide wheel cores

The wheel cores of guide wheels are usually made of metal materials and are mainly divided into the following types:

Stainless steel wheel cores: 316L stainless steel core + food-grade polyurethane encapsulation, FDA certified, suitable for pharmaceutical and food processing industries.

Aluminum wheel cores: Aluminum wheel cores are light in weight and have good corrosion resistance, suitable for weight-sensitive applications such as AGV trolleys and medical equipment.

Cast iron wheel cores: Iron wheel cores have high strength and load-bearing capacity, suitable for heavy machinery and equipment such as mining machinery and heavy forklifts.

Selecting the right wheel core material requires comprehensive consideration based on the specific application scenarios, load requirements, and environmental conditions of the equipment.

Use scenarios

Polyurethane tread guide wheels are widely used in the following fields:

Conveying systems: In logistics, warehousing, and other conveying systems, guide wheels are used to guide conveyor belts or conveyor vehicles along predetermined tracks to ensure efficient material transportation.

Automated equipment: In automated production lines, guide wheels help manipulators, robots, and other equipment to achieve precise positioning and movement, improving production efficiency and product quality.

Stacker: Ensure that the stacker maintains the correct direction during horizontal walking and vertical lifting, improve positioning accuracy, and operating efficiency.

Medical equipment: Antibacterial coating + silent design, operating noise ≤55dB, guides the precise movement of moving parts.

Heavy machinery: In heavy machinery such as construction machinery and mining equipment, guide wheels bear high loads to ensure the normal operation of equipment in complex environments.

Polyurethane tread guide wheels have become an indispensable key component in modern mechanical systems due to their super wear resistance, high load, chemical corrosion resistance, resilience, and other properties. When selecting, factors such as load, environment, and maintenance cost should be considered comprehensively to maximize efficiency.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane-Injected Model Idler Wheels

Polyurethane-Covered Bearing Wheels