Polyurethane-Injected Model Idler Wheels

Polyurethane-injected model idler wheels are primarily used to support and guide transmission components, such as conveyor belts, chains, or other moving elements, ensuring they run smoothly along their predetermined trajectory.

Technical Information

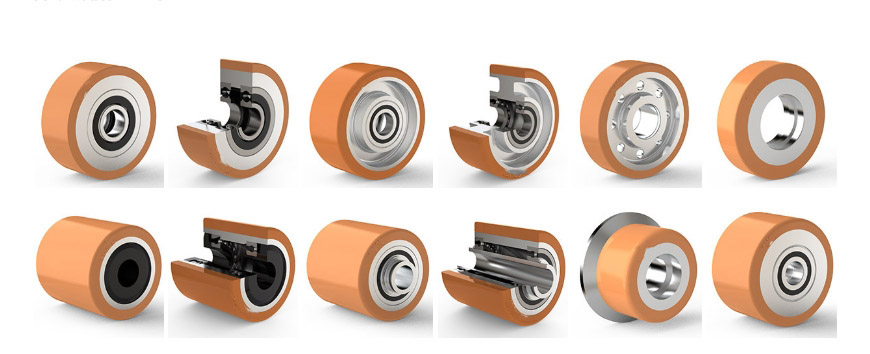

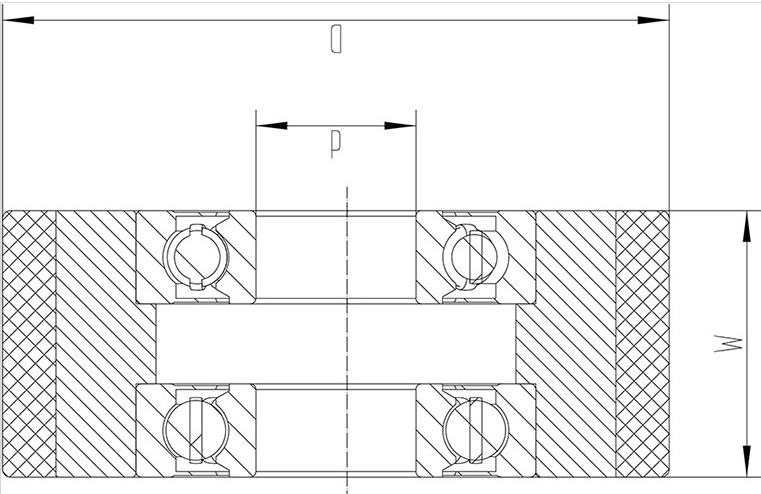

Polyurethane-injected model idler wheels, also known as the passive wheel, are an indispensable component of the mechanical system. It is primarily used to support and guide transmission components, such as conveyor belts, chains, or other moving elements, ensuring they run smoothly along their predetermined trajectory. The passive wheel does not directly drive the system, but optimizes the mechanical performance by adjusting the tension, changing the direction of movement, or providing necessary support.

Characteristics of polyurethane wheels

Polyurethane materials have significant advantages in the manufacture of passive wheels due to their excellent physical and chemical properties:

High wear resistance: Polyurethane wheels have excellent wear resistance and can withstand high-load wear for a long time, extending their service life.

Impact resistance: Polyurethane wheels have good impact resistance and can absorb impact energy to a certain extent, effectively preventing the wheels from being damaged.

Strong load-bearing capacity: The strength and toughness of polyurethane wheels enable them to withstand enormous loads and are suitable for heavy equipment and high-load occasions.

Noise reduction and shock absorption: The elastic properties of polyurethane materials enable the wheels to effectively reduce noise and vibration during operation and improve operating comfort.

Strong environmental resistance: Polyurethane materials can withstand harsh environmental factors such as ultraviolet radiation, ozone and grease, and are suitable for a variety of complex working conditions.

Strong customization: Polyurethane wheels can be customized in size, hardness and color according to specific needs to meet the requirements of different application scenarios.

Application scenarios of idler wheels

Polyurethane idler wheels are widely used in multiple industries, mainly including:

Logistics and transportation: In the conveying systems of airports, ports and storage centers, polyurethane passive wheels are used to support and guide conveyor belts to ensure efficient transportation of goods.

Mining: Polyurethane idler wheels are used in mining equipment to withstand high loads and impacts in harsh environments to ensure stable operation of equipment.

Industrial manufacturing: In the fields of automobile, machinery and electronic product manufacturing, polyurethane idler wheels are used in various transmission and handling equipment to improve production efficiency.

Agricultural machinery: Agricultural machinery such as tractors and harvesters use polyurethane idler wheels to adapt to complex terrain and reduce soil compaction.

Polyurethane casting model idler wheels can assist the drive wheel to maintain equipment balance, share heavy loads, and help improve equipment performance and production efficiency.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Load-Bearing Support Wheels with Shock-absorbing Oil-resistant

Polyurethane Tread Guide Wheel