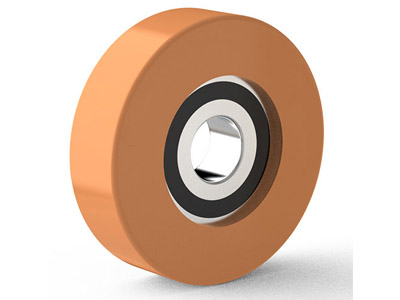

Polyurethane Load-Bearing Support Wheels with Shock-absorbing Oil-resistant

Polyurethane load-bearing support wheels have the characteristics of high elasticity, wear resistance, high load-bearing capacity, and long service life. They are widely used in high-load scenarios such as logistics and automation.

Technical Information

Polyurethane load-bearing support wheels have become key components in industrial production equipment, logistics and transportation, and automated production lines due to their excellent durability and high load capacity. Whether it’s forklift trucks, automated guided vehicles (AGVs) in high-load environments, or rail vehicles with precision requirements, high-load capacity polyurethane wheels deliver stable support and extended service life. This article explores their features, types, and applications to help you select the best polyurethane wheels for heavy equipment.

Features of polyurethane load-bearing support wheels

• High load capacity

Polyurethane’s exceptional compressive strength allows single wheels to bear up to 3–5 tons, outperforming traditional rubber wheels.

• Superior abrasion resistance

The abrasion resistance of polyurethane is more than 3 times that of rubber, which is suitable for high-frequency and high-intensity working environments.

• Vibration and noise reduction

Adjustable elasticity and cushioning absorb shocks, reduce noise by up to 20 Bd, and protect equipment integrity.

• Chemical corrosion resistance

Ideal for harsh settings like chemical plants or ports, these wheels resist oil, acids, and alkalis.

• Anti-skid design

Tread patterns (herringbone, diamond) ensure a high friction coefficient, enhancing safety in wet or oily conditions.

Types of polyurethane load support wheels

• By structure

Fixed support wheels: Simple installation for linear motion systems.

Steering support wheels: Equipped with bearings for agile directional changes.

• By size

Small (φ100–200mm): Perfect for AGV carts and light machinery.

Medium (φ200–400mm): Common in logistics forklifts and conveyor systems.

Large (φ400mm+): Built for mining and heavy machinery.

| Performance | Properties | Product parameters | |||||

| Hardness | PU hardness at 20℃ | Shore | 75A | 80A | 85A | 90A | 95A |

| Tensile strength | Tensile strength | MPa | 18 | 26 | 35 | 38 | 45 |

| Elongation at break | Elongation at break | % | 600 | 580 | 550 | 530 | 500 |

| Tear strength | Tear propagation resistance: | kN/m | 50 | 60 | 73 | 105 | 120 |

| (without nick) | |||||||

| Abrasion | Abrasion loss | mm³ | 45 | 40 | 30 | 30 | 30 |

| Density | Density | g/ cm³ | 1.14 | 1.14 | 1.15 | 1.16 | 1.17 |

| Operating temperature | Working temperature | ℃ | -60~70℃ | ||||

| Resilience | Resilience | % | 50 | 55 | 50 | 48 | 40 |

| Compression set | Compression set | % | 25 | 23 | 22 | 20 | 18 |

| (deflection/22h/70℃) | |||||||

| Poisson's ratio | Poisson's ratio | / | 0.5 | 0.48 | 0.46 | 0.44 | 0.39 |

| Modulus of elasticity | Modulus | MPa | 5 | 20 | 40 | 60 | 80 |

| Coefficient of friction/steel | Friction coefficient/steel | / | 0.8 | 0.75 | 0.6 | 0.5 | 0.45 |

• By specialization

High-temperature wheels: Heat-resistant additives for foundries or kilns.

Anti-static wheels: Safeguard electronics and pharmaceutical facilities.

Explosion-proof wheels: Certified for flammable environments like mines.

Industries transformed by polyurethane support wheels

• Logistics & warehousing

Forklifts, pallet trucks, and automated sorting systems rely on polyurethane wheels with high load ratings to minimize downtime.

• Automation & robotics

Agvs and RGVs use these wheels for smooth, stable navigation in smart factories.

• Rail transport

Light rail and monorail systems depend on polyurethane support wheels for precision guidance and durability.

• Heavy machinery

Mining and lifting equipment benefit from wheels that withstand impacts and extreme loads.

• Electronics manufacturing

Cleanroom-compatible wheels meet strict hygiene and static-control standards.

At Philson, we specialize in customizing polyurethane wheels with high load ratings for diverse applications. Whether you need the best polyurethane wheels for heavy equipment or specialized designs for unique environments, contact us for tailored solutions.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Heavy-Duty Polyurethane-Coated Wheels

Polyurethane-Injected Model Idler Wheels