Heavy-Duty Polyurethane-Coated Wheels

Heavy-duty polyurethane-coated wheels are chemically coated with polyurethane on heavy iron core, aluminum core or copper core wheel hubs. The polyurethane tread is chemically inert, non-sparking, non-conductive, and will not leave marks on the floor.

Technical Information

Heavy-duty polyurethane-coated wheels are chemically coated with polyurethane on heavy iron core, aluminum core or copper core wheel hubs. The polyurethane tread is chemically inert, non-sparking, non-conductive, resistant to ozone, grease and most oils and solvents, and will not leave marks on the floor. Not easy to debond. The following is a detailed introduction to the parameters, advantages, and applicable scenarios of heavy-duty polyurethane wheels.

Physical properties of heavy-duty PU-coated wheels

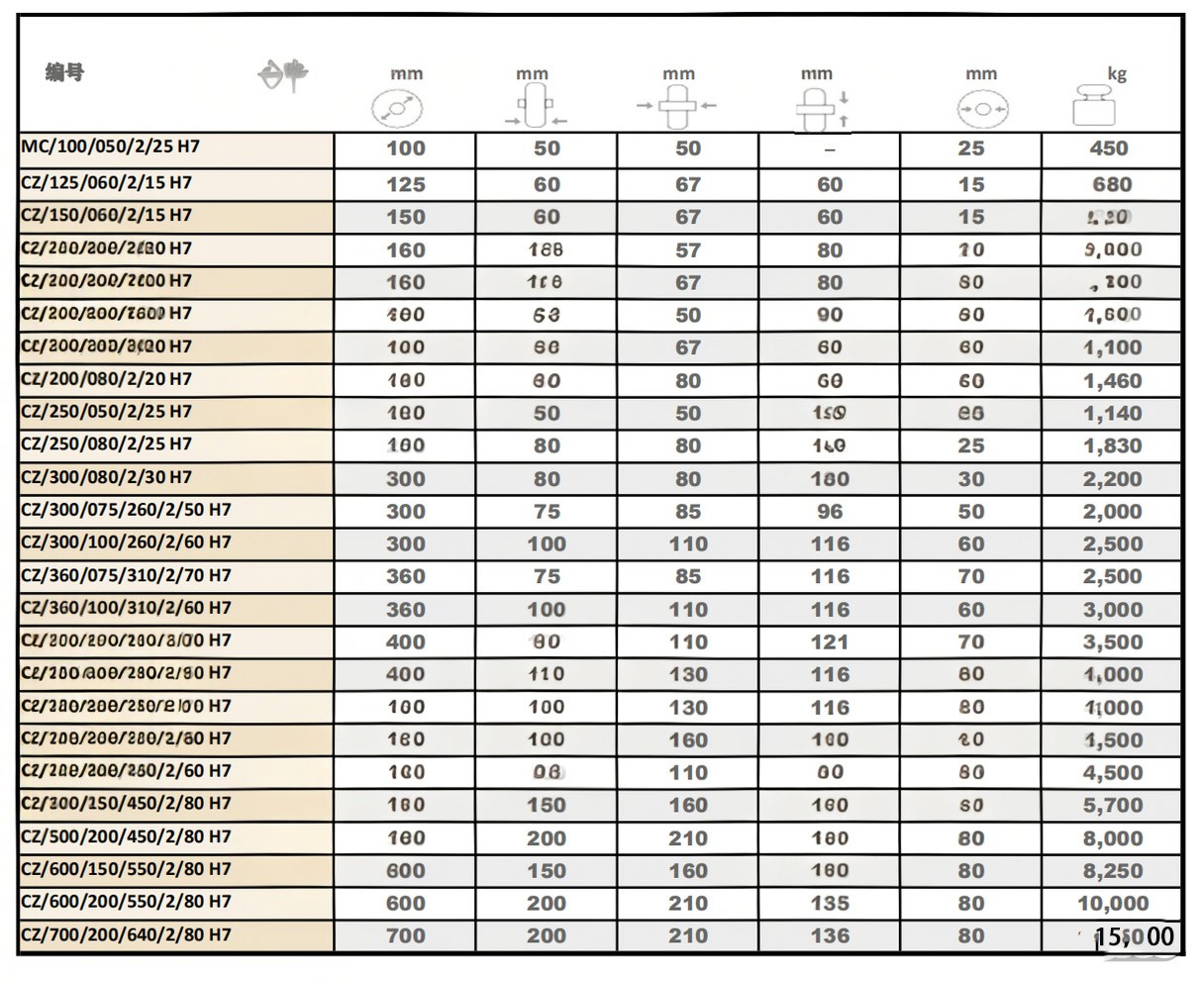

1. Load range: 450 – 15000 kg

2. Composition: advanced liquid cast polyurethane

3. Hardness: 90-95 Shore hardness (Shore A type)

4. Resilience: 29%

5. Elongation at break: 430%

6. Tensile strength: 7000-7400 psi

7. Abrasion resistance: 5-10 times that of ordinary materials

8. Temperature range: -50°C to +200°F (intermittent); 0°C to 180°F (continuous). Occasional steam cleaning will not damage it.

Advantages of high-load urethane-covered wheels

1. Excellent load-bearing capacity

2. Ultra-long service life

3. Shock absorption and noise reduction

4. Ground protection and anti-skid performance

5. Chemical corrosion resistance and environmental adaptability

6. Lightweight and energy-saving

7. Customized design

8. Low maintenance cost

Typical application scenarios of large-tonnage poly-coating wheels

I. Logistics and warehousing fields

1. Forklift and pallet truck driving wheel support wheel

2. Automated three-dimensional warehouse AGV (automatic guided vehicle) driving wheel universal wheel

3. Three-dimensional warehouse stacker guide wheel travel wheel

II. Manufacturing and industrial scenarios

1. Automobile production line transfer equipment conveyor wheel friction wheel

2. Steel and metal processing platform vehicle load wheel walking wheel

3. Bridge gantry crane and shield machine support wheel bearing wheel

4. Coal mine monorail crane wheel driving wheel limit wheel

III. Special environment and industry

1. Cold chain logistics and cold storage drive wheel driven wheel

2. Anti-static and low flame retardant wheels for clean rooms in food and pharmaceutical factories

Heavy duty polyurethane rubber-coated wheels have become the first choice for industrial applications due to their excellent performance and durability. They not only improve work efficiency, but also reduce maintenance costs and ensure long-term operation of equipment. If you are looking for efficient and reliable wheel solutions, Philson heavy duty polyurethane coated wheels are undoubtedly your best choice.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Heavy Duty Polyurethane-Driven Wheel

Polyurethane Load-Bearing Support Wheels with Shock-absorbing Oil-resistant