- +86-19941574798

- sale06@kfqizhongji.com

Application

High Wear-Resistant Polyurethane Wheels for Roller Coasters

Amusement Equipment Wheels

High Wear-Resistant Polyurethane Wheels for Roller Coasters

High wear-resistant polyurethane wheels for roller coasters are characterized by low rolling resistance, high load durability, smooth ride, chemical corrosion resistance and high durability (low maintenance cost).

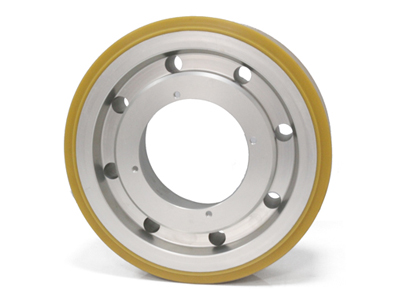

KBK Crane Rail Wheel Re-Coating with Polyurethane

Heavy Machinery

KBK Crane Rail Wheel Re-Coating with Polyurethane

Re-coating the polyurethane wheel is a necessary measure when the wheel is debonded, broken, or has low operating efficiency. It is the key to ensure the safe and efficient operation of KBK cranes.

Airport Luggage Trolley Transfer Polyurethane Drive Wheel

Special Equipment

Airport Luggage Trolley Transfer Polyurethane Drive Wheel

Airport luggage trolley transfer polyurethane drive wheels facilitate the movement of luggage, cargo and equipment throughout the airport, carrying heavy objects while providing quiet, smooth and fast operation, durable and safe.

Textile Machinery Polyurethane-Coated Wheels

Special Equipment

Textile Machinery Polyurethane-Coated Wheels

Textile machinery polyurethane-coated wheels are widely used in spinning machines, looms, dyeing and finishing equipment, etc., due to their excellent wear resistance, high load-bearing capacity, low noise, and stability.

LCD Panel Cleanroom Polyurethane Drive Wheel

Semiconductor Workshop Equipment

LCD Panel Cleanroom Polyurethane Drive Wheel

LCD panel cleanroom polyurethane drive wheels are engineered to meet the ultra-strict demands of LCD manufacturing, where contamination control, precision, and reliability are critical.

Photolithography Machine Polyurethane Guide Wheel

Semiconductor Workshop Equipment

Photolithography Machine Polyurethane Guide Wheel

Photolithography machine polyurethane guide wheels are critical components in semiconductor manufacturing, ensuring contamination-free, ultra-precise movement in photolithography systems.

Semiconductor Wafer Transport Urethane Wheels

Semiconductor Workshop Equipment

Semiconductor Wafer Transport Urethane Wheels

Semiconductor wafer transport urethane wheels are used in clean rooms and have the characteristics of high wear resistance, low heat generation, fatigue resistance, no powder loss, anti-static, and low resistance.

Mining Machinery Monorail Crane Travel Wheel

Mining Monorail Hoisting Equipment

Mining Machinery Monorail Crane Travel Wheel

Mining machinery monorail crane travel wheels ensure smooth, safe, and efficient movement of monorail cranes when transporting heavy loads, ore, and equipment on underground and open-pit mining sites.

Categories

Recent Cases

Recent Products

Copyright © 2025 Philson Intelligent Equipment. All Rights Reserved XML Sitemap