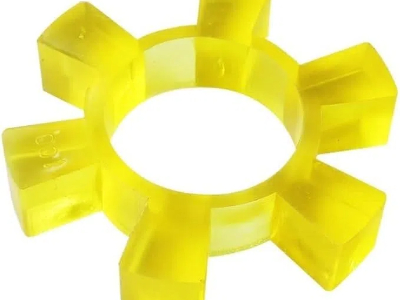

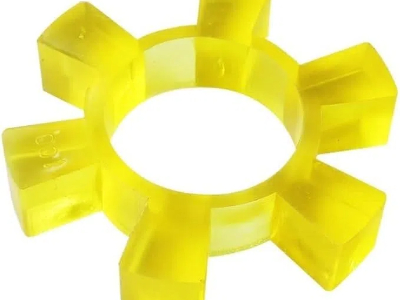

Flexible Gear Polyurethane Coupling

The flexible gear polyurethane coupling is used to connect two shafts and transmit torque while compensating for any misalignment between the two shafts. It has excellent shock absorption and wear resistance.

Technical Information

Flexible gear polyurethane coupling is designed to connect two shafts and transmit torque while compensating for any misalignment between them. Polyurethane coupling offers superior shock absorption, vibration damping, and wear resistance, making it an ideal choice for ensuring the smooth and efficient operation of mechanical systems. It is widely used in industries such as automation, heavy machinery, and logistics, delivering reliable performance under various working conditions.

Working principle of flexible gear polyurethane coupling

Flexible gear polyurethane couplings consist of two gear rings (an inner gear ring and an outer gear ring) with a highly elastic polyurethane insert between them. The working mechanism involves:

Connection of gear rings:

The inner gear ring is connected to the driving shaft, while the outer gear ring is connected to the driven shaft. When the driving shaft rotates, the inner gear ring transmits torque to the polyurethane elastomer.

Misalignment compensation:

Flexible gear polyurethane couplings compensate for axial, radial, and angular deviations that may occur during installation or operation, reducing mechanical stress and preventing premature wear.

Advantages of polyurethane flexible coupling

• Excellent shock absorption and damping

The elastic nature of polyurethane enables flexible gear polyurethane couplings to absorb and dissipate vibrations and shocks during torque transmission. This reduces noise levels and minimizes mechanical stress on the system.

• Superior wear and corrosion resistance

Polyurethane offers excellent resistance to wear, oil, and chemical corrosion, ensuring that the coupling maintains its performance in harsh environments such as high temperatures, humidity, and chemically aggressive conditions.

• Low maintenance and reduced operating costs

Unlike traditional rigid couplings, flexible gear polyurethane couplings require minimal maintenance and lubrication. This significantly reduces operating costs while enhancing system reliability.

• Lightweight and compact structure

The lightweight and compact design of polyurethane couplings reduces the load on the equipment, increasing system efficiency without compromising strength and durability.

• Low noise and environmentally friendly

Polyurethane materials reduce noise levels during operation, making these couplings suitable for environments that prioritize low-noise operation and environmental sustainability.

Application scenarios of spider insert couplings

• Automated production lines and industrial robots

Flexible gear polyurethane couplings are widely used in automated production lines and robotic systems, where they ensure high-precision torque transmission and smooth operation of complex equipment.

• Heavy machinery and mining equipment

In heavy-duty industrial applications such as mining and construction, flexible gear polyurethane couplings withstand high loads and severe working conditions, providing reliable performance and minimizing downtime.

• AGV/RGV logistics and transportation equipment

Automated guided vehicles (AGVs) and rail-guided vehicles (RGVs) in modern logistics systems require high-precision, low-maintenance couplings to ensure smooth and efficient movement. Flexible gear polyurethane couplings provide the necessary reliability for uninterrupted operation.

Why choose Philson flexible gear polyurethane couplings?

Philson flexible gear polyurethane couplings stand out for their superior performance in a variety of industrial applications. With their ability to absorb shock, compensate for misalignment, and withstand harsh environments, they are the first choice for efficient and low-maintenance mechanical systems. By ensuring smooth torque transmission and minimizing mechanical stress, Philson couplings not only extend equipment life but also reduce operating costs, making them a valuable asset in modern industrial environments. Philson is committed to providing the most cost-effective polyurethane solutions. Please feel free to contact us!

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Customized Polyurethane Special-Shaped Parts Manufacturers

Cast Anti-Collision Polyurethane Plates