- +86-19941574798

- sale06@kfqizhongji.com

Heavy Machinery

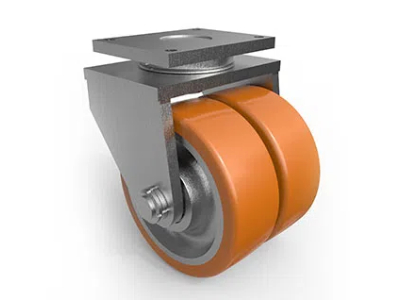

Application of Polyurethane Heavy-Duty Universal Wheels

Polyurethane heavy-duty universal wheels are widely used in logistics, industrial manufacturing, warehousing, aviation, and many other fields due to their excellent wear resistance, load-bearing capacity, and flexibility.

Polyurethane heavy-duty universal wheels are widely used in logistics, industrial manufacturing, warehousing, aviation, and many other fields due to their excellent wear resistance, load-bearing capacity, and flexibility. Compared with traditional rubber wheels or metal wheels, polyurethane wheels have higher load-bearing capacity, low noise, anti-skid, and corrosion resistance, so they have become the first choice for various heavy equipment.

Core features of polyurethane universal wheels

•Superior load-bearing capacity and impact resistance

The load-bearing capacity of polyurethane wheels can reach several tons or even dozens of tons, far exceeding traditional rubber wheels and plastic wheels. Whether it is heavy equipment or a high-frequency operating environment, polyurethane wheels can stably carry loads to avoid deformation or cracking of wheels due to overload.

•Low noise, shock absorption effect

Polyurethane materials have good elasticity and shock absorption ability, which can effectively reduce vibration and noise when equipment moves, and are very suitable for places with high requirements for quietness, such as hospitals, office buildings, laboratories, and other environments.

•Strong wear resistance and corrosion resistance

Polyurethane wheels have excellent wear resistance and can maintain good shape and performance even under frequent use or high loads. In addition, polyurethane materials have high corrosion resistance to grease, chemicals, and moisture, allowing them to maintain stable performance even in harsh environments.

• High elasticity and tear resistance

The high elasticity of travel wheels not only provides good shock absorption, but also makes them highly tear-resistant when hit by heavy objects. This feature can effectively prevent the wheels from being damaged in complex environments.

• Flexible steering and stable operation

The universal wheel has a 360° flexible steering function, which can easily cope with various complex paths and improve the flexibility and maneuverability of the equipment. At the same time, the low rolling resistance of polyurethane materials ensures that the equipment moves smoothly without getting stuck or vibrating.

• High temperature resistance and anti-aging

Polyurethane wheels have good high-temperature resistance and can operate normally under extreme temperature conditions. At the same time, its excellent anti-aging performance can effectively extend the service life and reduce maintenance costs.

What equipment are urethane omnidirectional wheels used for?

• Material handling equipment

Heavy-duty trolleys and platform trucks: Heavy-duty trolleys and platform trucks are often used for material handling in factories and warehouses. Polyurethane wheels can carry up to several tons of weight while maintaining smooth movement and avoiding damage to the ground.

• Industrial equipment and automated production lines

Automated guided vehicles (AGVs) and robots: In modern automated production lines, AGVs and industrial robots frequently shuttle between various areas. Polyurethane universal wheels provide excellent flexibility and wear resistance to ensure stable operation of the equipment.

• Warehousing and logistics systems

Heavy-duty shelves, pallet mobile equipment: Pallet transportation equipment and heavy-duty shelf systems in the warehousing industry need to have high flexibility and load-bearing capacity. PU universal wheels ensure that the equipment can be easily moved to avoid damage to the ground.

• Aviation and defense fields

Aviation maintenance equipment: Aircraft maintenance platforms and heavy aircraft handling equipment need to have superb load-bearing capacity and wear resistance. Polyurethane universal wheels can easily cope with such high-load applications.

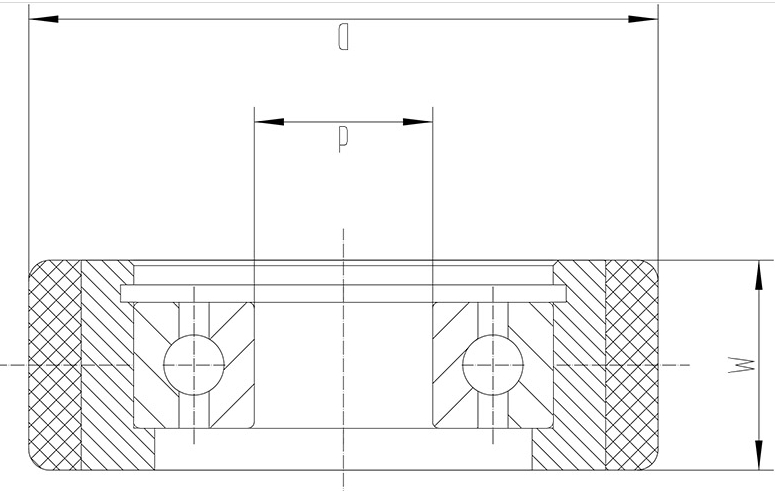

Custom polyurethane heavy-duty universal wheels

According to the different needs of customers, we can provide customized PU multi-directional wheels solutions, including:

• Wheel size and diameter customization: Adapt to the specifications and load requirements of different equipment.

• Wheel surface hardness selection: Different hardnesses can be selected according to the equipment load to ensure optimal performance.

• Anti-corrosion coating and special materials: Special materials are provided for wheels in corrosive environments to improve the durability of the wheels.

• Customized rotation flexibility: Adjust the sensitivity and flexibility of the universal wheel according to the movement needs of the equipment.

If you are looking for high-performance polyurethane heavy-duty universal wheels or need a customized solution to meet specific application needs, please contact our technical team. We will provide you with professional advice and high-quality products to help your equipment achieve the best performance!

Elevator Column Lift Guide Wheels

KBK Crane Rail Wheel Re-Coating with Polyurethane