- +86-19941574798

- sale06@kfqizhongji.com

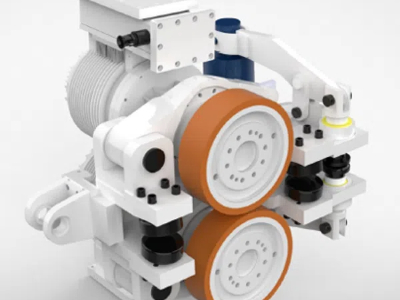

Mining Monorail Hoisting Equipment

Coal Mine Monorail Crane Polyurethane Drive Wheel

Coal mine monorail crane polyurethane drive wheels are used in coal mines, with excellent properties such as high rebound and high tear strength, and can meet the use of diesel vehicles, battery vehicles and pneumatic monorail cranes.

Coal mine monorail crane polyurethane drive wheels are essential components in the operation of monorail cranes used for transporting materials within coal mines. These drive wheels are designed to ensure the smooth and efficient movement of the crane along its rail system, providing reliable and durable performance in harsh mining environments.

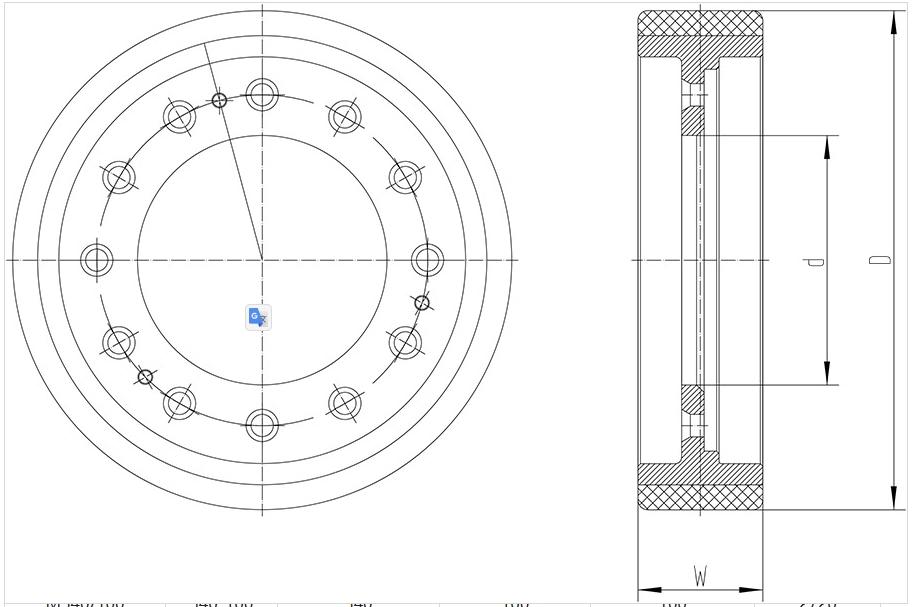

Durability for harsh mining conditions

Coal mine monorail crane polyurethane drive wheels are engineered to withstand the tough conditions commonly found in mining operations. The polyurethane material offers superior abrasion resistance, allowing the wheels to endure the constant wear from the mine's environment, including exposure to dust, dirt, and moisture. This durability ensures long-lasting performance, minimizing downtime and reducing the need for frequent replacements.

High load capacity and efficiency

Mining cast iron polyurethane-coating wheels are built to handle high load capacities, essential for transporting heavy materials within the mine. These wheels provide efficient power transmission, ensuring that the crane moves with optimal speed and reliability, even when carrying heavy loads. The robust design of the drive wheels ensures that the crane system operates efficiently, reducing energy consumption while improving overall productivity.

Noise reduction and vibration dampening

Mining polyurethane drive wheels contribute to a quieter and more stable operation. The elasticity of the polyurethane material helps to absorb shocks and vibrations, resulting in a smoother ride and reducing noise levels. This feature is particularly beneficial in mines where noise reduction is crucial for safety and worker comfort.

Corrosion and chemical resistance

Anti-static PU wheels offer excellent resistance to corrosive substances commonly found in mining environments, such as oils, chemicals, and moisture. The polyurethane material’s chemical resistance helps to protect the wheels from degradation, ensuring they maintain their performance even in harsh and wet conditions. This corrosion resistance extends the lifespan of the wheels, reducing maintenance costs and improving the overall reliability of the crane system.

Customizable for specific mining needs

Low-flame-retardant polyurethane wheels can be customized to meet the specific requirements of different mining operations. Wheels can be tailored in terms of size, hardness, and load capacity, allowing them to be adapted to various crane models and operational needs. This customization ensures that the drive wheels perform optimally for the unique demands of each mining operation, providing maximum efficiency and safety.

Coal mine monorail crane polyurethane drive wheels are crucial for the safe and efficient operation of monorail cranes in mining environments. Their durability, load capacity, noise reduction, and resistance to chemicals and corrosion make them indispensable for maintaining a smooth and productive operation in harsh conditions. By investing in high-quality polyurethane drive wheels, mining operators can enhance operational efficiency, reduce maintenance costs, and ensure the longevity of their monorail crane systems.

none

Mining Anti-Static Cast Polyurethane Wheel