- +86-19941574798

- sale06@kfqizhongji.com

Mining Monorail Hoisting Equipment

Heavy-duty Underground Transportation Polyurethane Wheels

Heavy-duty underground transportation polyurethane wheels play a critical role in facilitating the movement of goods and materials in underground mining, tunneling, and other subterranean environments.

Heavy-duty underground transportation polyurethane wheels play a critical role in facilitating the movement of goods and materials in underground mining, tunneling, and other subterranean environments. These wheels, made with durable polyurethane material, are designed to enhance the performance of various types of underground transport systems, including conveyor belts, mining carts, and rail-guided vehicles (RGVs).

Durability and longevity in harsh conditions

Underground transportation polyurethane wheels are designed to withstand the harsh conditions commonly found in underground environments. Polyurethane’s superior resistance to abrasion, corrosion, and chemical exposure ensures that the wheels maintain their performance in the face of challenging conditions such as moisture, dust, and temperature fluctuations. This durability extends the lifespan of the wheels, reducing maintenance costs and the need for frequent replacements.

Guide wheels for accurate navigation

Heavy-duty polyurethane wheels serve as guide wheels, helping rail-guided vehicles (RGVs) and mining carts stay aligned on their designated paths. These wheels are designed to support the vehicle’s movement along tracks or magnetic strips, ensuring that the transportation system operates efficiently and accurately. The guide wheels minimize the risk of deviation, which is especially important when navigating tight spaces or long underground tunnels.

Friction wheels for smooth operation

Poly transportation wheels also function as friction wheels, playing an important role in providing traction for the vehicle. The high grip provided by polyurethane allows the wheels to maintain a strong hold on tracks or surfaces, preventing slipping and ensuring smooth and controlled movement. This frictional quality is crucial in underground environments where maintaining stability is key to preventing accidents and optimizing efficiency.

Drive wheels for power transmission

Polyurethane-coating wheels are also used as drive wheels in various systems, such as conveyor belts or monorail cranes. The drive wheels work by transferring power from the motor to the vehicle, ensuring that the system operates smoothly. Polyurethane’s excellent load-bearing capacity ensures that the wheels can handle heavy materials and continue to perform efficiently even under heavy stress.

Noise reduction for safe operations

Polyurethane-covered roller wheels contribute to noise reduction in underground operations. The resilience of polyurethane helps absorb vibrations and shocks during movement, reducing the overall noise produced by the transportation system. This feature is especially valuable in environments where noise control is essential for both worker safety and comfort.

Corrosion and chemical resistance

Underground injection polyurethane wheels are highly resistant to chemicals, oils, and moisture commonly encountered in underground environments. The chemical resistance of polyurethane ensures that the wheels maintain their integrity even when exposed to harsh substances, helping to prevent degradation and extend the lifespan of the wheels. This resistance makes polyurethane wheels ideal for use in industries like mining, where chemical exposure is common.

Underground transportation polyurethane wheels are indispensable for efficient and reliable operations in underground environments. Whether serving as guide wheels, friction wheels, or drive wheels, these polyurethane wheels provide the durability, traction, and resistance necessary to meet the unique demands of subterranean transportation systems. Investing in high-quality polyurethane wheels ensures improved operational efficiency, reduced maintenance costs, and enhanced safety in underground transportation.

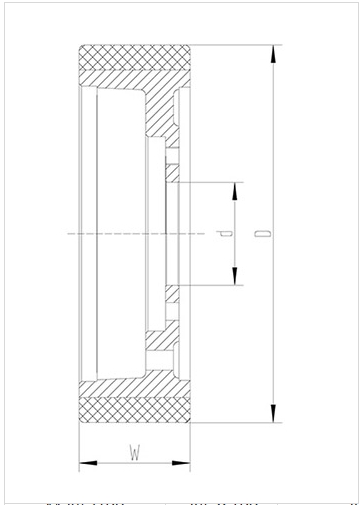

Mining Anti-Static Cast Polyurethane Wheel

Mining Machinery Monorail Crane Travel Wheel