Heavy-Duty Cast Iron Polyurethane Wheels

Heavy-duty cast iron polyurethane wheels combine strength, durability, and ground protection. These wheels combine cast iron's strong load-bearing capacity with polyurethane's elastic, wear-resistant, and non-marking characteristics.

Technical Information

Heavy-duty cast iron polyurethane wheels combine strength, durability, and ground protection. These wheels combine cast iron's strong load-bearing capacity with polyurethane's elastic, wear-resistant, and non-marking characteristics. They are suitable for various high-load equipment such as coal mine monorail cranes, transfer vehicles, cranes, shield machines, stackers, etc. The following introduces the structure, characteristics, and application scenarios of heavy-duty cast iron polyurethane wheels.

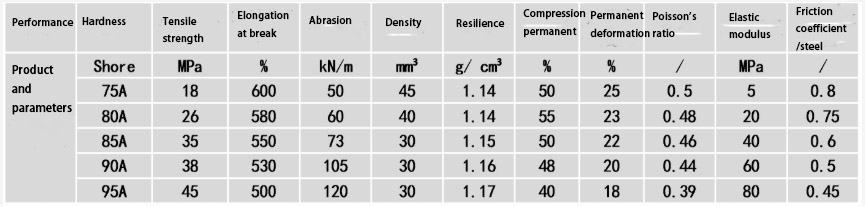

Key parameters of heavy-duty cast iron polyurethane wheels

Diameter and width

Diameter ranges from 4 inches to more than 12 inches

Width is usually 2 inches to 6 inches

Load capacity

The rated load capacity of a single wheel is usually more than 1,000 pounds, and some models can even withstand up to 20,000 pounds. Reasonable load matching can prevent premature damage.

Hardness (Shore hardness)

Polyurethane treads are measured in Shore A hardness (softer) or Shore D hardness (harder). Heavy-duty wheels usually use Shore D hardness (70-95), which strikes a balance between wear resistance and slight flexibility to absorb impact.

Axle specifications

Axle diameter (e.g., 1-inch to 2.5-inch) and material (hardened steel) ensure compatibility with mechanical equipment and resistance to bending under pressure.

Bearing types

Roller bearings are commonly used for heavy loads, offering durability and smooth rotation. Sealed bearings keep debris out, reducing maintenance.

Temperature resistance

Polyurethane performs best between -40°F and 200°F, making these wheels suitable for cold warehouses and high-temperature environments.

The size, hardness, load-bearing capacity, rigidity, and flexibility of polyurethane wheels can be customized.

Key features

Load capacity: The combination of a cast iron core and polyurethane tread enables these wheels to handle considerable weight. For example, some models can carry loads of up to 11,000 pounds.

Durability: The cast iron core ensures structural strength, while the polyurethane tread offers excellent wear resistance, resulting in a long service life and low maintenance costs.

Floor protection: The polyurethane tread is non-marking, resilient, and cushioning, protecting floors from damage and reducing operating noise.

Chemical resistance: Polyurethane is resistant to a wide range of chemicals, oils, and greases.

Temperature resistance: These wheels typically operate effectively in temperatures ranging from -40°F to +180°F, making them suitable for a wide range of industrial environments.

Applications and use cases

Heavy-duty cast iron polyurethane wheels are used in a variety of applications due to their versatile properties:

Industrial machinery: Used in CNC machines, presses, and assembly lines to ensure smooth operation of heavy equipment without damaging the floor.

Material handling: Forklifts, pallet trucks, and delivery trucks benefit from their load-bearing capacity and comfortable tread in logistics centers.

Automotive and aerospace: Polyurethane wheels are essential for assembly line conveyors and aircraft component transporters, where precision and load stability are critical.

Construction and mining: Rough terrain and gravel-filled environments require wheels that are puncture-resistant and can withstand the heavy loads of cranes or drills.

Medical and institutional equipment: Patient beds and MRI machines take advantage of their quiet operation and reliable performance to ensure patient comfort and safety.

Outdoor applications: Certain polyurethane formulations are designed to withstand outdoor conditions, making these wheels ideal for outdoor use.

Selection considerations

Load requirements: Make sure the wheel’s load capacity matches the weight needs of the application.

Surface conditions: Assess surface type and condition to select a wheel with the appropriate hardness and tread design for optimal traction and surface protection.

Environmental considerations: Consider exposure to chemicals, extreme temperatures, and outdoor environments to select wheels with appropriate material properties.

Bearing type: Select the appropriate bearing (e.g., precision ball bearings, roller bearings) based on the required maneuverability and load capacity.

Mounting configuration: Determine the necessary mounting style, such as swivel, rigid, or braked, to meet maneuverability and safety requirements.

Heavy-duty cast iron polyurethane wheels offer unmatched durability and adaptability. By aligning their parameters—such as size, load rating, and hardness—with specific operational needs, businesses can enhance productivity and safety. Whether navigating factory floors, construction sites, or healthcare facilities, these wheels deliver performance where it matters most.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Aluminum Polyurethane Rubber Wheels

Cleanroom Polyurethane-Coating Travel Wheels