- +86-19941574798

- sale06@kfqizhongji.com

Special Equipment

EMS Polyurethane Friction Drive Wheel

EMS polyurethane friction drive wheels have the characteristics of wear resistance, impact resistance, low noise operation, etc., and are widely used in automobile manufacturing, semiconductor production, and other fields.

The EMS (Electrical Monorail System) polyurethane friction drive wheel has become an efficient and reliable material transportation solution in the fields of industrial automation, such as automobile manufacturing, semiconductor production, and food processing, due to its excellent wear resistance, impact resistance, and low noise operation.

What is an EMS?

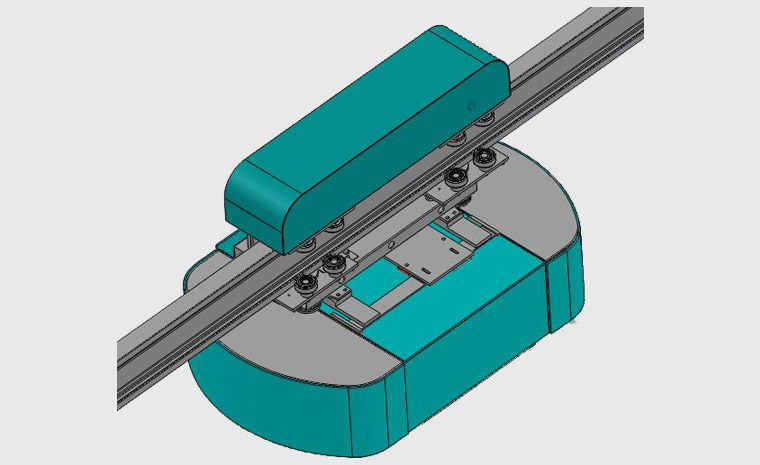

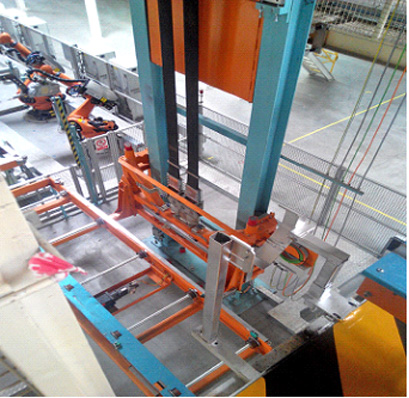

The EMS is an automated conveying system that is often used above the production line of a factory. The trolley is suspended on the track through an electric monorail system to transport and carry materials. The EMS system can flexibly move horizontally and vertically, is suitable for complex production line layouts, and can greatly improve the efficiency of material flow.

The operation of the aerial suspension trolley depends on high-performance friction drive wheels and load wheels, which determine the running stability, load capacity, and system life of the trolley on the track. Among them, the polyurethane wheel has become an indispensable component in the EMS system due to its superior performance.

Advantages of the EMS Polyurethane friction drive wheel

• Excellent wear resistance

Polyurethane materials have extremely high wear resistance, which can effectively reduce wheel wear and extend the service life of the EMS system. Even in high-load and high-speed operation environments, they can maintain stable performance.

• High load-bearing capacity and impact resistance

EMS polyurethane wheels have excellent load-bearing capacity and impact resistance, can withstand long-term heavy-load transportation, and effectively reduce shock in the event of collision, protecting the track and system components.

• Low-noise operation

Compared with metal or other hard materials, polyurethane wheels generate less noise during operation, which helps create a quiet production environment and improve the working comfort of employees.

• Oil and chemical resistance

Polyurethane tread drive wheels have excellent oil and chemical resistance, and can be used for a long time in harsh industrial environments without being affected by chemical corrosion.

• Good friction and grip

Polyurethane materials can provide stable friction and grip to prevent sliding and deviation, ensuring the precise movement and positioning of EMS trolleys on the track.

• Improve production efficiency

EMS Polyurethane-coated wheels can run at high speeds while maintaining stable load-bearing capacity, making material handling more efficient and significantly shortening production cycles.

• Reduce equipment maintenance costs

Since polyurethane wheels have good wear resistance and impact resistance, they can reduce the cost of repairing and replacing the system due to wear or failure.

Flexible customization: EMS wheels of different hardness, size, and specifications can be customized according to customer needs to meet the special requirements of different industries.

Application industries of EMS PU load wheels

• Automobile manufacturing industry

EMS systems are widely used to transport car bodies, parts, and other related materials on automobile production and assembly lines. The high load-bearing capacity and stability of polyurethane wheels ensure the efficient operation of the production line.

• Electronics and semiconductor industries

EMS wheels are widely used in electronic components, PCB circuit boards, and semiconductor production lines. The low noise and precise positioning capabilities of polyurethane wheels ensure the safe transportation of sensitive components.

• Food and beverage industry

EMS systems undertake material transportation tasks in food and beverage production lines. The oil and corrosion resistance of polyurethane wheels ensures long-term stable operation in high hygiene requirements.

EMS wheels, as an important part of the EMS conveying system, play a vital role in the automated production lines of many industries. Polyurethane trolley wheels have become the best choice for various industries to improve production efficiency and reduce maintenance costs due to their excellent wear resistance, impact resistance, low noise, and chemical corrosion resistance.

Airport Luggage Trolley Transfer Polyurethane Drive Wheel

none