- +86-19941574798

- sale06@kfqizhongji.com

Special Equipment

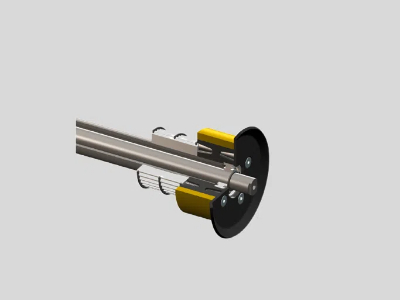

Polyurethane-Coated Conveyor Rollers

Polyurethane-coated conveyor rollers offer superior load-bearing capacity, reduced noise levels, and excellent resistance to abrasion, chemicals, and oils.

Polyurethane-coated conveyor rollers offer superior load-bearing capacity, reduced noise levels, and excellent resistance to abrasion, chemicals, and oils. Their flexibility and ability to perform under extreme conditions make them ideal for applications requiring consistent and smooth material transport.

PU-coated conveyor rollers key characteristics

Exceptional durability: Resistant to abrasion, oils, chemicals, and UV exposure, ensuring longevity even in harsh environments.

• High load-bearing capacity: Maintain structural integrity under heavy loads without deformation.

• Noise reduction: Polyurethane’s elastic properties minimize operational noise compared to metal or plastic rollers.

• Precision surface texture: Customizable coatings provide optimal grip or slip resistance for specific materials.

• Low maintenance: Resistant to wear and tear, reducing downtime and replacement costs.

• Customizable hardness and size: Available in various hardness levels and dimensions to meet industry-specific requirements.

Functions of polyurethane-coated roller

• Material handling: Ensures smooth and consistent transportation of products across conveyor systems.

• Shock absorption: Reduces impact damage during material movement, protecting sensitive goods.

• Friction control: Provides optimal friction to maintain product positioning and prevent slippage.

• Noise reduction: Creates a quieter working environment by minimizing operational noise.

Industries of use

Polyurethane-coated conveyor rollers are widely applied across industries where reliable material handling is essential, including:

• Furniture industry: For the smooth transport of furniture parts during manufacturing.

• Door industry: Ensuring efficient handling of doors and related components.

• Flooring industry: Facilitating seamless movement of flooring materials in production lines.

• Wood-based panel industry: Enhancing processing efficiency of panels and boards.

• Printed circuit board (PCB) industry: Supporting delicate circuit board transportation with minimal impact.

• Photovoltaic industry: Enabling secure movement of solar panel components.

• Plastic cards industry: Ensuring precision and protection in card handling processes.

• Insulation boards industry: Facilitating smooth movement of insulation materials.

• Glass industry: Safeguarding glass sheets from damage during transportation.

With their unmatched versatility and performance, polyurethane-coated conveyor rollers enhance production efficiency, reduce maintenance costs, and ensure smooth operation across multiple industries.

Textile Machinery Polyurethane-Coated Wheels

Airport Luggage Trolley Transfer Polyurethane Drive Wheel