- +86-19941574798

- sale06@kfqizhongji.com

Material Handling Drive System

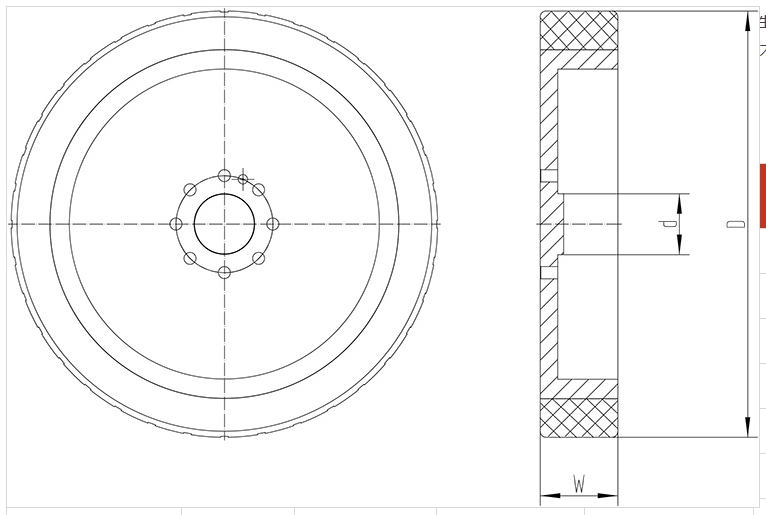

Rail-Guided Vehicle (RGV) PU Wheels in Automated Material Handling

Rail-guided vehicle (RGV)(shuttle) PU wheels are critical components in automated material handling systems, facilitating efficient and reliable transportation within warehouses and industrial environments.

Rail-guided vehicle (RGV)(shuttle) PU wheels are critical components in automated material handling systems, facilitating efficient and reliable transportation within warehouses and industrial environments. These wheels, typically coated with polyurethane (poly), are designed to meet the specific demands of shuttle systems and RGVs, offering durability, noise reduction, and floor protection.

Durability and load capacity

Rail-guided vehicle (RGV) poly wheels are engineered to withstand heavy loads and continuous operation. The polyurethane coating provides high abrasion resistance and tear strength, ensuring longevity even under demanding conditions. This durability is essential for maintaining the efficiency of automated systems that rely on consistent and reliable performance.

Noise reduction and floor preservation

Shuttle poly-coated wheels contribute to a quieter working environment by minimizing noise during operation. The soft polyurethane material absorbs shocks and vibrations, reducing the noise generated as the vehicles move along their tracks. Additionally, these wheels offer good floor preservation by minimizing wear and tear on flooring surfaces, which is crucial in maintaining the integrity of warehouse floors.

Low rolling resistance

Rail-guided vehicle (RGV) polyurethane-coated wheels are designed to have low rolling resistance, which enhances the energy efficiency of the vehicles. This characteristic allows shuttles and RGVs to operate more smoothly and with less energy consumption, leading to cost savings and improved system performance.

Customization and versatility

Polyurethane wheels can be customized to meet specific operational requirements. Manufacturers offer various sizes, load capacities, and hardness levels to suit different applications within automated systems. This versatility ensures that the wheels can be tailored to the unique needs of each facility, optimizing performance and efficiency.

Shuttle poly wheels play a pivotal role in the functionality and efficiency of automated material handling systems. Their durability, noise reduction capabilities, low rolling resistance, and customization options make them indispensable components in modern warehouses and industrial environments. Investing in high-quality poly wheels ensures the longevity and reliability of shuttle and RGV systems, ultimately contributing to streamlined operations and cost savings.

Three-Dimensional Storage Stacker Polyurethane Wheels

none