- +86-19941574798

- sale06@kfqizhongji.com

Material Handling Drive System

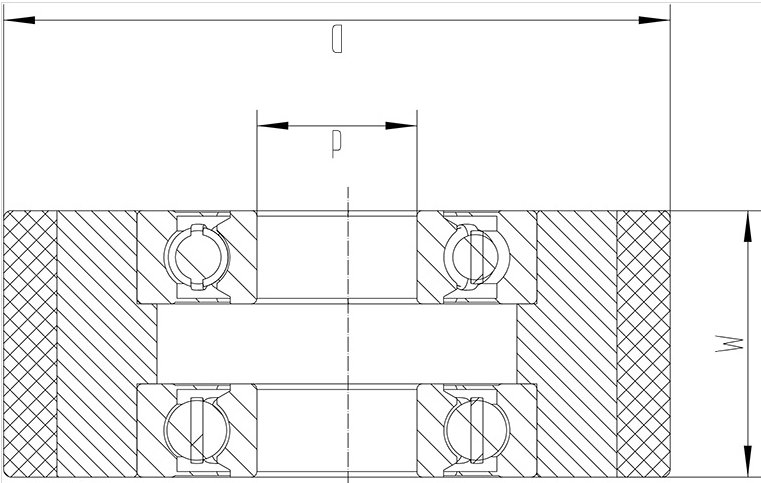

Three-Dimensional Storage Stacker Polyurethane Wheels

Three-dimensional storage stacker polyurethane wheels are critical components in modern automated storage and retrieval systems (AS/RS).

Three-dimensional storage stacker polyurethane wheels are critical components in modern automated storage and retrieval systems (AS/RS). Designed to handle heavy loads, ensure precision movement, and minimize wear, these wheels enhance efficiency in warehouses, manufacturing facilities, and logistics centers. Below, we explore their equipment applications, functional roles, and unique characteristics.

Enhanced load-bearing capacity for heavy-duty operations

Three-dimensional storage stacker polyurethane wheels excel in supporting high-capacity loads within vertical storage systems. Their polyurethane construction combines elasticity with rigidity, enabling them to withstand constant pressure from stacked pallets or containers. Integrated into stacker cranes and shuttle cars, these wheels distribute weight evenly, reducing stress on motors and rails. This durability ensures reliable performance in high-intensity environments, from cold storage facilities to industrial warehouses.

Precision guide wheels for smooth navigation

Guide wheels are a specialized type of stacker PU wheel responsible for maintaining alignment in storage systems. Their tapered or flanged design ensures seamless contact with guide rails, preventing lateral deviations during vertical or horizontal movements. Polyurethane’s low-friction surface minimizes resistance, allowing stackers to navigate tight aisles and narrow racks without jerking or misalignment. This precision reduces downtime and optimizes storage density in space-constrained facilities.

Noise reduction in high-traffic environments

Unlike metal or hard plastic alternatives, poly wheels operate quietly due to the material’s vibration-dampening properties. This is especially vital in 24/7 warehouses or facilities near noise-sensitive areas. The wheels’ shock absorption also protects delicate goods from vibrations during transport. Equipment like automated retrieval carts benefit from smoother, quieter operations, enhancing workplace safety and comfort.

Chemical and moisture resistance for harsh conditions

Storage stacker urethane wheels resist oils, solvents, and moisture, making them ideal for harsh industrial environments. In food processing or pharmaceutical storage, where sanitation is critical, polyurethane’s non-porous surface prevents bacterial growth. Guide wheels and drive wheels in these settings maintain traction and structural integrity even when exposed to cleaning agents or temperature fluctuations, ensuring uninterrupted workflows.

Longevity in demanding storage applications

The exceptional wear resistance of polyurethane wheels extends the equipment's lifespan. Their ability to endure repetitive motion without cracking or deforming reduces maintenance costs. In automated systems, where wheels are in near-constant use, polyurethane’s resilience translates to fewer replacements and higher roi. This reliability is crucial for industries prioritizing uptime, such as e-commerce fulfillment centers.

Three-dimensional storage stacker polyurethane wheels are indispensable in optimizing automated storage systems. From heavy-duty load-bearing to precision guidance, their versatility and durability address the challenges of modern logistics. By investing in these wheels, businesses achieve smoother operations, lower noise levels, and long-term cost savings—key factors in staying competitive in fast-paced industries.

AGV Polyurethane-Covered Guide Wheels

Rail-Guided Vehicle (RGV) PU Wheels in Automated Material Handling